Researchers from Zhejiang University, Zhejiang Sci-Tech University, and the University of Cambridge developed a novel miniaturized spectrometer using common plastic materials. The innovative technology was recently published in the journal Science Advances DOI: 10.1126/sciadv.adu4225 and featured as the cover article.

This research offers a low-cost, highly stable, and easily mass-producible solution. The researchers incorporated plastic materials into miniaturized spectrometers to achieve spatial spectral encoding by their birefringence effects. This approach eliminates the need for traditional photolithography processes, enabling large-scale manufacturing of broadband miniaturized spectrometers. Covering a broad spectral range from visible to short-wave infrared (400 – 1600 nm), the miniaturized spectrometer demonstrates outstanding line-scan imaging capabilities and promises extensive applications.

“By shaping the internal stress within the polymer, we are able to engineer spectral behaviour with high repeatability and tunability, something that’s incredibly difficult to achieve with conventional optics said Professor Zongyin Yang, the lead researcher of the project.

Inspired by Smartphone Cameras

Today's smartphone cameras rely on high-performance plastic lenses combined with sophisticated algorithms to deliver stunning images—so why not plastic for spectrometers? Inspired by this, researchers have introduced a novel plastic prism using shape-memory polymers (SMPs). By precisely inducing gradient stress in epoxy films, they achieved controlled spectral dispersion from visible to short-wave infrared (400–1600 nm). This innovation not only replaces expensive optical elements but also unlocks new possibilities for compact, affordable, and high-performance spectroscopy.

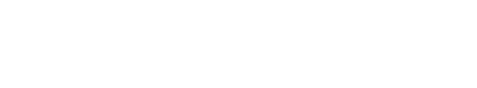

Fig. 1. Application and characterization of plastics. (A and B) illustration of plastic replacing glass in small camera and spectrometer modules, respectively. (C) Birefringence of plastic products in the laboratory. (D) Illustration of birefringence effect. (E) the introduction of stress into the network. (F) Glass transition curves of epoxy film on the DMA. (G) DMA curves of strain, stress, and temperature during internal stress programming. (H) the stress retention of epoxy compared to the stress relaxation of PMMA.

Turning Plastic into Rainbows: Revealing the Physics

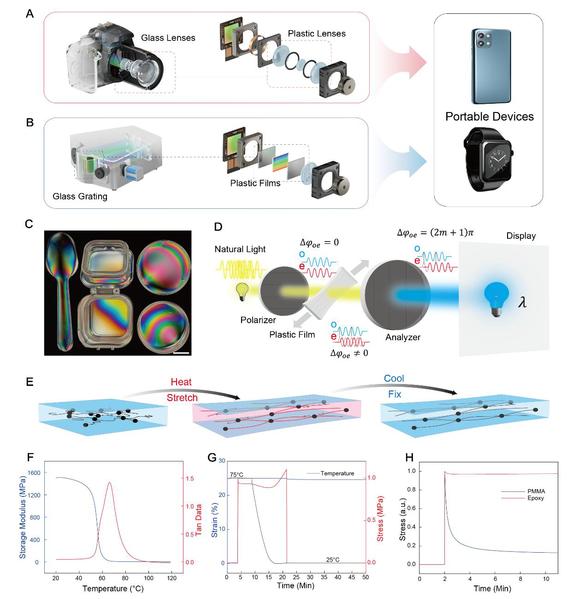

Fig. 2. Design of stress and dispersion engineering in epoxy films. (A - C) Simulation and experimental results of rectangular films stretching. (D - F) Simulation and experimental results of triangle films stretching. (G) Simulation and experimental results of large-scale film stretching. (J) Schematic diagram of the designed system for producing stress-engineered filters.

Plastic products often exhibit rainbow-like colors under polarized light, resulting from stress-induced birefringence—varying internal stresses create distinct color patterns (Figure 1). Inspired by this phenomenon, the researchers precisely manipulated internal stresses within plastics through controlled stretching. Experiments showed significant color and spectral changes in rectangular and triangular plastic samples at different stretch ratios. Impressively, researchers demonstrated high-throughput manufacturing by producing nearly 50 spectral-gradient films simultaneously on a 12 cm × 12 cm plastics substrate, designing a scalable and cost-effective production line (Figure 2).

Lost-Cost, High-Performance, and Portable Spectroscopy

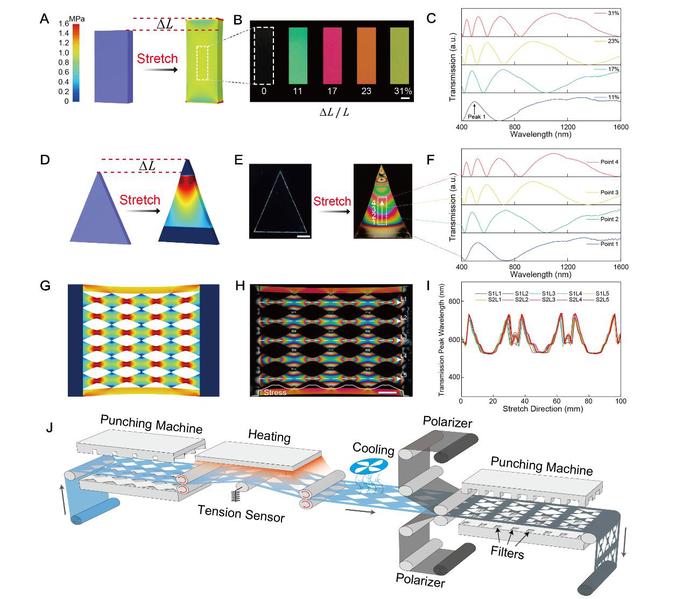

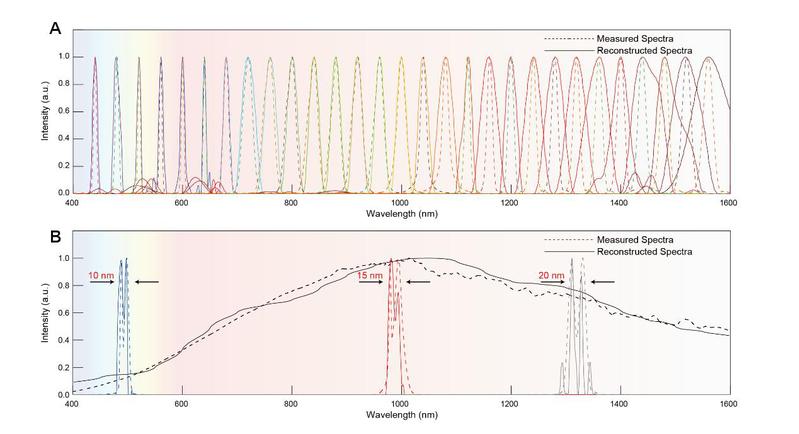

Fig. 3. Schematic diagram, reconstruction, and spectral imaging results of the spectrometers. (A) Picture of miniaturized spectrometer. (B) Schematic and operation of the spectrometer. (C) Response functions of the spectrometer. (D) Reconstruction of 19 monochromatic spectra. (E) Reconstruction of a double- peak spectrum separated by 10 nm. (F) Reconstruction of a halogen lamp spectrum. (G - I) Spectral imaging results.

Traditional spectrometers are often bulky and expensive, limiting their application in consumer electronics, environmental monitoring, and medical diagnostics. This new plastic-based approach enables a compact, low-cost alternative by directly integrating plastic spectral films directly onto commercial CMOS image sensors to form a compact spectrometer device. Coupled with computational algorithms, these systems accurately reconstruct spectral signatures and support applications in spectral imaging (Figure 3).

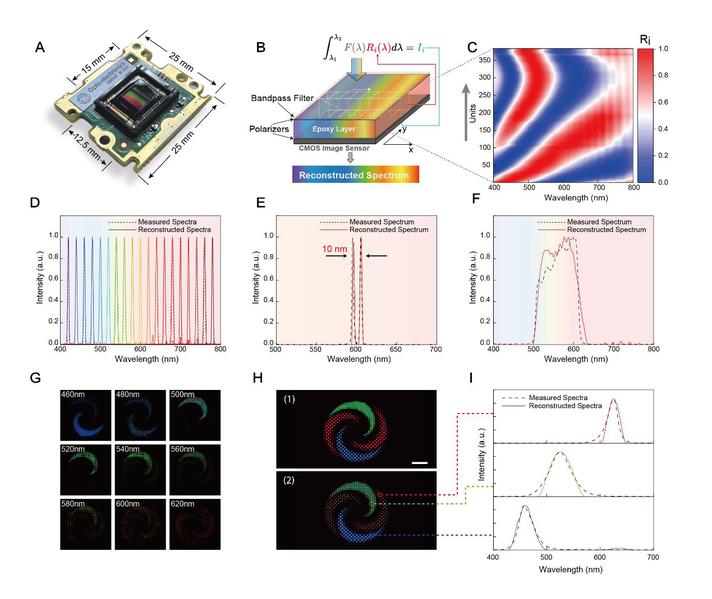

Fig. 4. Reconstruction performance of the ultra-broadband spectrometers. (A) Reconstruction of monochromatic spectra with different wavelengths varying from 400 to 1600 nm compared with measured spectra using commercial spectrometers. (B) Reconstruction of double-peak spectra and a broadband tungsten light source spectrum.

Reconstruction performance demonstrated excellent accuracy with a visible-range resolution of 10 nm and an average peak error of only 0.73 nm across the broader 400–1600 nm range (Figure 4). This innovation not only revolutionizes micro-spectrometer technology but also opens new pathways for wearable devices, implantable sensors, and next-generation consumer electronics.